The modular engine family exists more on the drawing board (or computer CAD system) than on the production line.

Only on the drawing board can you chop off 2 cylinders from a V8 to create a V6. Only on the drawing board can you weld on 2 cylinders to an I4 to create an I6.

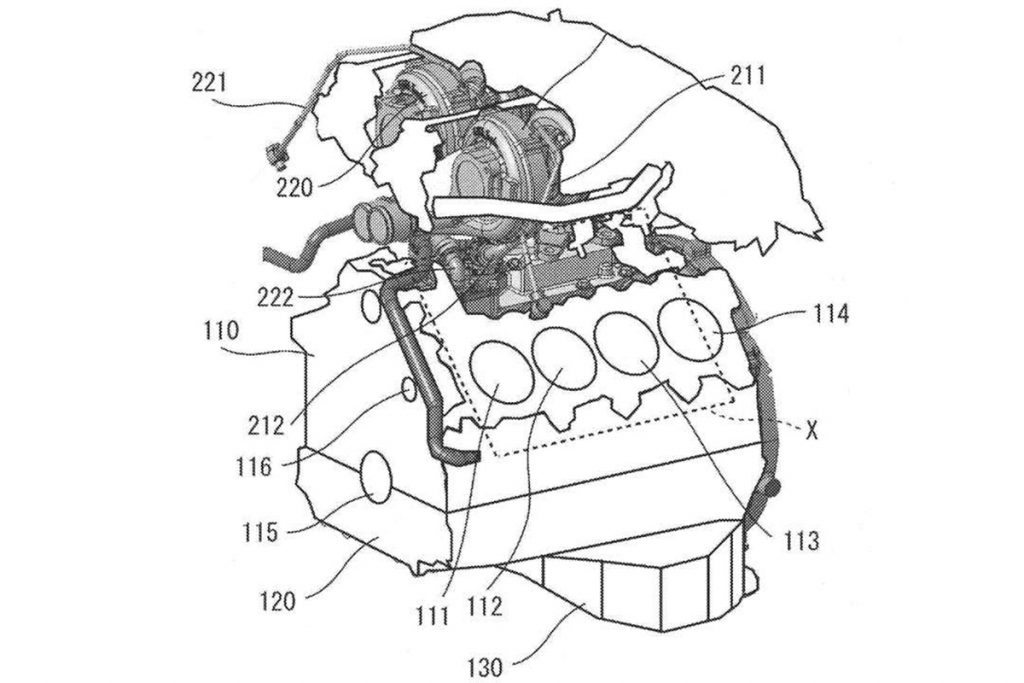

When they built it, MB did not and could not just saw off the last row of cylinders from their finished V8 (the crankshaft had to be changed to match the different firing pattern of the V6, for one), even though this is seemingly what they did on the drawing board. And while a 90deg V is a good configuration for a V8, it is not a good configuration for a V6, where a 60deg is a better fit for minimizing NVH.

When they build it, MB does not and can not just build 3 I4 engines, saw one in half and weld each half to each of the other 2 engines, to create 2 I6 engines from 3 I4 engines (the crankshaft has to change to match the different firing pattern of the I6, for one, and the 50% longer crankshaft has be stronger to avoid flexing), even though this is seemingly what they did on the drawing board. And creating the I6 was the easy part; now MB cannot fit in under the shorter hood of the new C-Series. A new, more versatile, shorter (60deg) V6 would have been a better fit, all around (and a V6 can fit transversely for FWD models, adding to its versatility).

Each different engine block, despite how it was created on the drawing board, requires its own die and tooling; and the crankshaft, for one, is unique not only for the configuration of the engine (I3, I4, I6, V6, V8) but its different compression ratios (if compression ratios differ for normal, turbocharged and hybrid engines, for example).